Sustainability stands out.

Exhaust gas cooling and the associated exhaust gas purification system in energy-intensive industrial processes are increasingly coming to the fore in times of energy transition and increased ecological awareness among the population and in industry. The metal industry in particular has always struggled with a "dirty" image. This makes it all the more important for plants to be proactive in shaping these issues so as not to be overrun by regulatory constraints.

Water-cooled know-how.

Our engineers develop ideas and concepts for exhaust gas cooling and exhaust gas cleaning systems in hot gas lines, afterburner chambers, converter hoods and chimneys and all other water-cooled exhaust gas ducts for a wide variety of melting units such as lead furnaces, copper furnaces or slag treatment furnaces.

Would you like to expand the production capacity of your electric arc furnace and need a custom-fit exhaust gas cooling system for this concept?

Would you like to integrate a dust chamber into your hot gas line as an exhaust gas cleaning system and at the same time extract heat and use it for other purposes?

Or are you simply looking for a manufacturer for your exhaust gas cooling or exhaust gas treatment system?

The six KSK quality criteria in exhaust gas cooling.

Clearly arranged

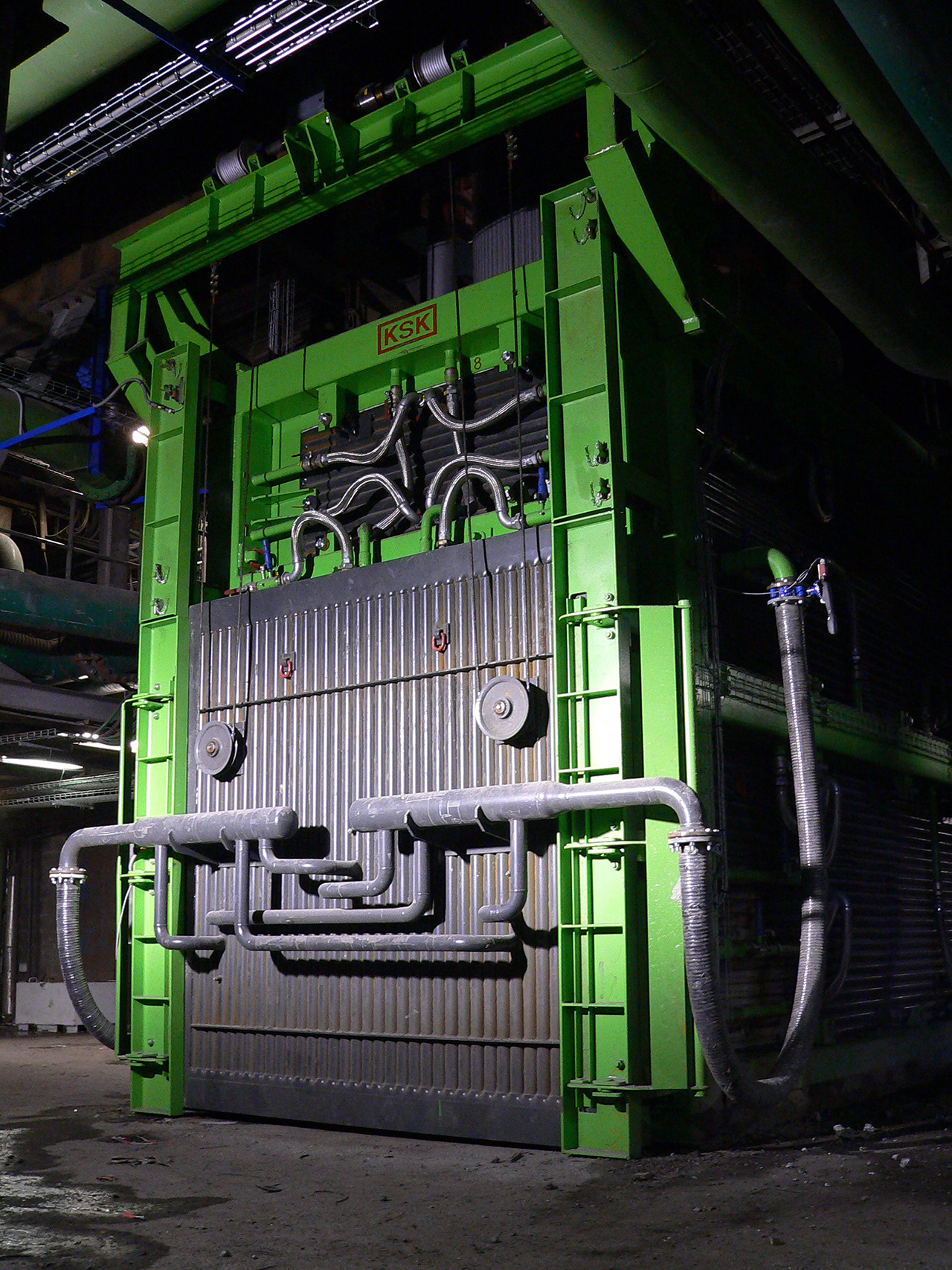

During operation, it is easy to lose track of where the cooling water is flowing through the hot gas duct. Perhaps this is also the reason for the rapid wear of your exhaust gas cooling system? These and similar questions often arise. That's why we always design our hot gas ducts, converter hoods and other water-cooled exhaust gas cleaning systems in such a way that the water flow is as simple and clear as possible. See for yourself and visit various reference systems with us.

Functional

Are you looking for a solution to adjust the amount of false air at the inlet to the hot gas duct behind your electric arc furnace so that you burn off excess CO gas completely? Or do you need to swivel the entire hinged section to make room for the scrap basket? We will be happy to work with you to develop functional solutions that ensure greater work safety and make your waste gas cooling system easier to use on a day-to-day basis.

Innovative

Special challenges call for special solutions! Is warm water cooling not enough for your hot gas duct? Do you want to utilize waste heat on a large scale and operate your hot gas duct like a converter stack under high pressure and hot water? Or are you more concerned about the details of your converter hood? Our engineers will be happy to think through your questions about waste gas cooling together with you and support you with new ideas and technical innovations.

Perfect fit

No classic hot gas duct in pipe construction is suitable for the exhaust gas section of your melting furnace? No problem. We always develop our concepts and designs for acceleration sections, exhaust gas flaps or breeches (pieces) and other exhaust gas cleaning systems on a customized basis so that they fit smoothly into an (existing) exhaust gas cooling system.

Maintenance-friendly

We know what is important in everyday operations. The maintenance of exhaust gas cleaning systems, such as hot gas ducts, exhaust gas stacks and afterburner chambers, is labor-intensive and time-consuming. The wrong temperature level in your exhaust gas cooling system or an unfavorable choice of material for the exhaust gas stack of your recycling furnace will result in your colleagues' welding rods glowing more often than you would like. And at some point, the only solution is to completely replace the exhaust gas treatment system. We will be happy to help you work in a more carefree and relaxed manner. And if something really is not working, you can be sure that we will always send a technician to solve the problem - not a lawyer.

Economical

We develop our exhaust gas cooling and treatment systems as economically as technically possible. When designing them, we rely on our engineering expertise and do not carelessly add inappropriate safety factors and buffers. This saves investment and operating costs and makes the new exhaust gas cooling system a complete success for maintenance, operation and purchasing!

KSK's exhaust gas treatment systems generally comprise the primary or direct dedusting of a system. For an electric arc furnace, the exhaust gas treatment system usually consists of a furnace cover elbow, an afterburner chamber with dust discharge and a hot gas duct. As our exhaust gas treatment systems are designed as water-cooled pipe constructions, the exhaust gas is cooled by the cooling water flowing through the pipes. In the converter area, steam is generated on the pipe side as part of the exhaust gas cooling process.

We design our primary dedusting systems so that they can be integrated into your existing off gas treatment system with secondary dedusting and filter system on request. If you are planning a completely new flue gas cleaning system, we will be happy to assist you or potential project partners as experts in primary gas dedusting. On request, we can develop an exhaust gas cleaning system and exhaust gas cooling systems in general as a cold or warm water component or as a hot water component or steam generator. There are few geometric limits to a KSK off gas treatment system - it is always a custom-made product anyway.

Waste heat recovery

Industrial cooling

Table of contents

-

What is flue gas cleaning and why is it important?

- Definition and basics of flue gas cleaning

- Why Flue Gas Needs to Be Cleaned

- Important components of a flue gas stream

Effective flue gas cleaning: Everything you need to know

Flue gas cleaning is a critical technology in industry and power generation that aims to minimize the environmental impact of pollutant emissions. Through various processes and technologies, harmful components are removed from the flue gases to improve air quality and meet legal requirements. In this article, we will explain the basic aspects of flue gas cleaning, the pollutants to be removed, how the plants work, legal requirements and challenges.

What is flue gas cleaning and why is it important?

Definition and basics of flue gas cleaning

Flue gas cleaning is the process of removing pollutants from the flue gases produced by the combustion of fossil fuels in boilers, steel mills and other industrial facilities. This cleaning is necessary to protect the environment and human health by minimizing the emission of hazardous substances. Flue gas cleaning processes involve the use of various technical systems and chemical reactions to either physically separate or chemically neutralize the pollutants.

Why Flue Gas Needs to Be Cleaned

Flue gas contains a variety of pollutants, including gaseous substances such as sulfur dioxide (SO₂), nitrogen oxides (NOₓ), and volatile organic compounds, as well as solid particles and dust particles. These pollutants can cause serious environmental problems, such as acid rain and smog, and can be harmful to human health. Therefore, flue gas cleaning is essential to minimize these hazards. Other advantages of flue gas cleaning include compliance with legal requirements and the avoidance of financial penalties for exceeding specified limits.

Important components of a flue gas stream

A typical flue gas stream consists of various components, including water vapor, carbon dioxide (CO₂), nitrogen and water, as well as a mixture of harmful substances. The exact composition depends on the type of fuel and the combustion conditions. In addition to the non-hazardous components such as nitrogen and water vapor, gaseous pollutants and heavy metals such as mercury and dioxins are also present in the flue gas stream. These must be efficiently removed by the flue gas cleaning process before the cleaned gas is released into the atmosphere.

What pollutants are removed during flue gas cleaning?

Particles and dust particles

Dust particles are small, solid particles that are produced by the combustion of fuels and enter the atmosphere with flue gases. These dust particles can cause health problems such as respiratory diseases and pollute the environment by depositing into soils and water. Flue gas cleaning systems use various mechanisms such as electrostatic precipitation or filtration to remove these particles from the flue gas stream.

Dioxins and heavy metals

Dioxins and heavy metals such as lead, mercury and cadmium are particularly dangerous pollutants that are often released during industrial combustion processes. These substances can accumulate in the environment and cause health problems such as cancer or neurological disorders. Special separation and adsorption processes are used in flue gas cleaning to eliminate these highly toxic compounds. For example, heavy metals can be converted into stable compounds by adding chemicals and then adsorbed or separated.

Gaseous pollutants such as sulfur dioxide and nitrogen oxides

Sulfur dioxide and nitrogen oxides are major components of the flue gases produced by the combustion of fossil fuels. These substances contribute significantly to the formation of acid rain and smog. Flue gas cleaning uses processes such as absorption to neutralize sulfur dioxide through alkaline scrubbers. Nitrogen oxides are often converted into nitrogen and water by selective catalytic reduction (SCR) with the addition of ammonia to minimize environmental pollution.

How do flue gas cleaning systems work?

Mechanisms of separation and adsorption

The separation of pollutants from the flue gas can be based on various physical and chemical mechanisms. Electrostatic precipitation uses electric fields to remove particles from the flue gas stream. Adsorption, on the other hand, refers to the accumulation of pollutant molecules on the surface of a solid material, thus removing them from the gas. Activated carbon is a typical adsorbent, often used to remove organic pollutants and heavy metals.

Absorption and adsorption techniques

Absorption and adsorption are fundamental techniques for cleaning flue gas. In absorption, gaseous pollutants are dissolved in a liquid. One example is the removal of sulfur dioxide by an alkaline scrubbing process. In adsorption, on the other hand, pollutant molecules attach themselves to the surface of an adsorbent, such as activated carbon. Both techniques are often used together to achieve maximum cleaning efficiency.

Processes of electrostatic precipitation and dust removal

Electrostatic precipitation is an efficient process for removing dust particles from flue gases. In this process, the particles are charged by electric fields and then collected and separated on oppositely charged plates. This process is frequently used in power plants and industrial facilities. Dust removal can also be carried out by mechanical filters and cyclones, which separate the particles from the gas stream using centrifugal force or physical barriers.

What are the legal limits and regulations?

Overview of the BImSchV

The German Federal Emission Control Ordinance (BImSchV) defines the legal limits for the emission of pollutants into the environment. This ordinance serves as the basis for flue gas cleaning and ensures that emissions from industrial plants and power stations are reduced to a minimum. The BImSchV comprises different stages and specific regulations for different pollutants such as sulfur dioxide, nitrogen oxides and heavy metals.

Measuring and complying with limit values

Adherence to the legal limits requires regular measurements of the pollutant concentrations in the flue gas. These measurements are carried out by continuous emission monitoring systems that provide accurate data on pollutant emissions. The operators of flue gas cleaning systems are obliged to document this data and submit it to the authorities to ensure compliance.

Penalties for exceeding the limits

Severe penalties can be imposed if the specified limits are exceeded. These range from fines to plant closures. To avoid these consequences, many companies rely on advanced flue gas cleaning technologies and strict internal monitoring mechanisms. In addition, regular maintenance and optimization of the plants can help to ensure compliance with the limit values.

What are the challenges of flue gas cleaning?

Effective removal of heavy metals and dioxins

One of the biggest challenges in flue gas cleaning is the effective removal of heavy metals and dioxins. These pollutants are particularly difficult to break down and require specialized processes for safe and complete separation. Technologies such as activated carbon adsorption and catalytic processes are frequently used, but the efficiency of these methods must be constantly improved to meet strict legal requirements.

Use and recycling of separated materials

Another important consideration is the utilization and recovery of the materials that have been captured. To minimize environmental impact, the collected pollutants must be treated and disposed of safely or, in some cases, recycled. Materials such as heavy metals, for example, can be converted into new resources instead of simply being dumped. Innovations in this area can help improve both the environment and the economics of flue gas cleaning.

Optimization of Flue Gas Cleaning Processes

Finally, there is a constant challenge to optimize the flue gas cleaning processes. This requires continuous research and development as well as the implementation of new technologies. The aim is to increase the efficiency of pollutant removal and neutralization, and to minimize the energy consumption of the plants while reducing operating costs. Close cooperation between industry, research institutions and politics is needed to achieve these goals and to protect the environment sustainably.