All done.

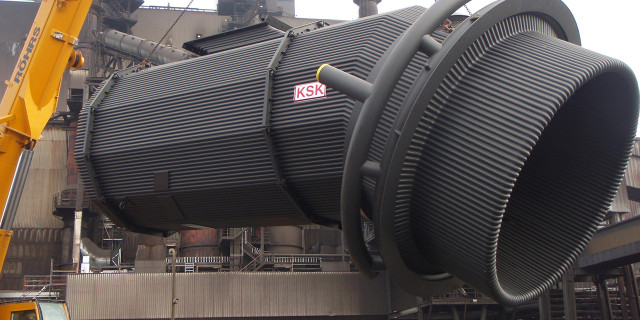

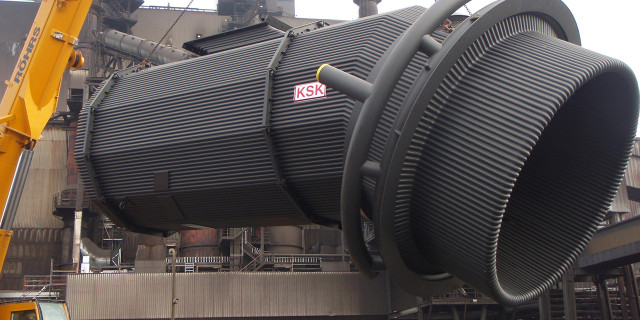

We build our components ourselves. At two locations in the middle of Germany, our production processes are tailored precisely to the further processing of steel tubes. Everything is geared towards manufacturing pipe constructions with a maximum weight of up to 40 tons for the harsh metallurgical environment. Our production processes, which are monitored by welding engineers, include cutting, forming, welding work including manual and semi-automated build-up welding, mechanical post-processing and corrosion protection. Due to the often special geometries of our individual parts, we increasingly rely on genuine and certified manual work.

See for yourself and pay a visit to our production facility.